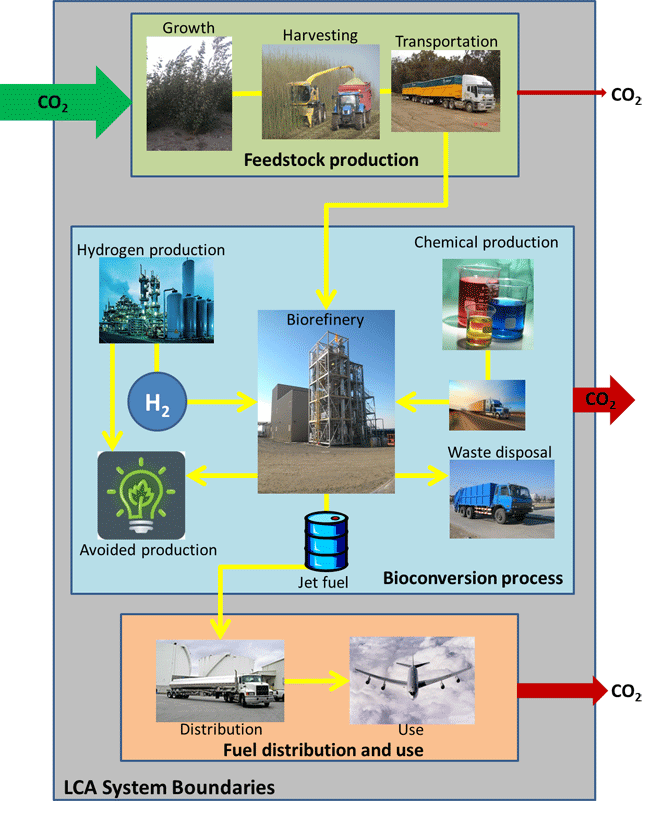

A major goal of AHB was to assess the sustainability and environmental impacts associated with production and use of fuels and chemicals produced in biorefineries from a poplar feedstock. To do so, we conducted a Life Cycle Assessment (LCA). An LCA is the most rigorous and complete way to assess environmental sustainability. LCAs measure environmental impacts over the entire life of a product, from creation, to use, and ultimately disposal. An LCA quantifies all resource consumption and emissions to the environment associated with a product and identifies areas where environmental performance can be improved. LCA results characterize how the production and use of a product affect the environment on a local, regional and global scale.

For example, the diagram below (Figure 1) illustrates the major elements of a life cycle assessment for the production of jet fuel from poplar wood grown on bioenergy farms. The system boundaries of the LCA are set to include all processes and products needed to create jet fuel made from poplar. Arrows that cross the system boundaries indicate use of raw materials (green arrows) or emissions to the environment (red arrows). Carbon dioxide (CO2) is used as an example in this case to show where it is consumed and where it is emitted during the fuel’s lifetime. The size of the arrow is proportional to the amount of CO2 flow at that point.

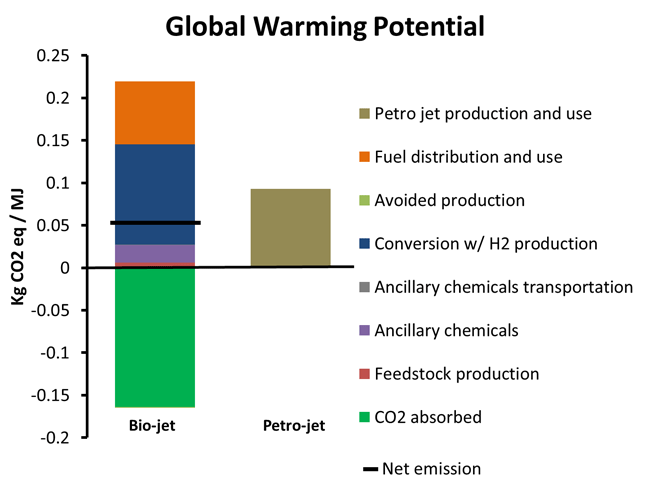

Environmental impacts can be assessed once all processes and associated emissions have been identified and quantified. Three important impact areas for biofuel production are Global Warming Potential (GWP), water use, and fossil fuel use. Presented below are the results from our research.

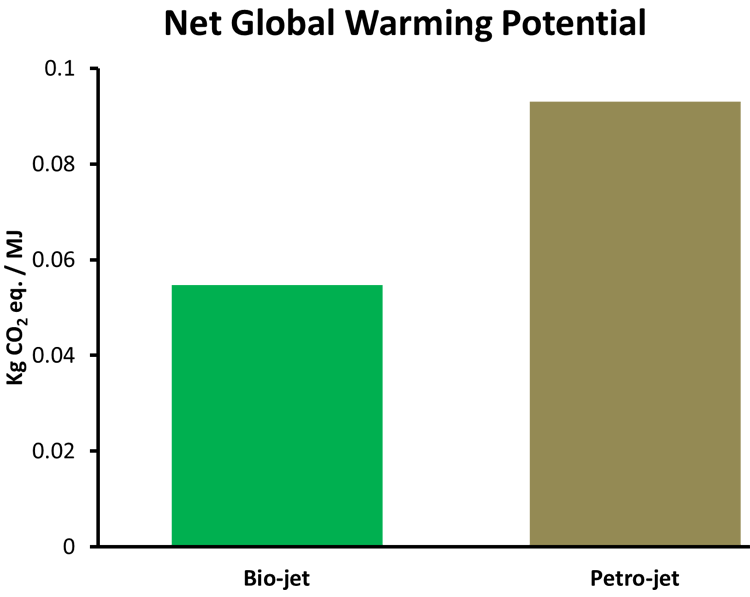

- Figure 2 compares the GWP of poplar-produced jet fuel to that of conventional petroleum-based jet fuel. GWP incorporates all greenhouse gas emissions to an equivalent emission of CO2.

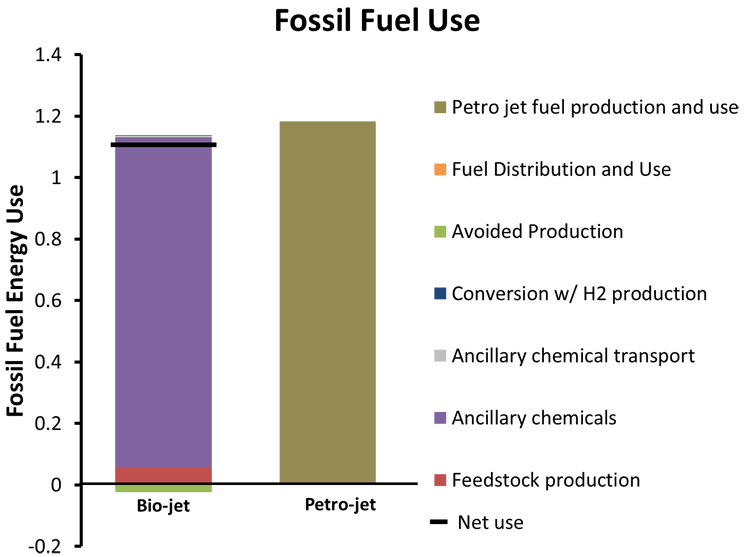

- The net GWP makes it easier to make comparisons between poplar and petroleum-based jet fuels (Figure 3). Net GWP from bio-jet is much lower than petro-jet.

- Both bio-jet and petro-jet require fossil fuels for the conversion process (Figure 4). For the bio-jet most of the fossil fuel use comes from natural gas to make hydrogen needed for drop-in fuels.

Positive contributions to GWP are primarily related to combustion in the biorefinery (light green) and the use of fuel (orange). Negative contributions result from carbon dioxide sequestration from the growing poplar trees (dark green) and the displacement of fossil fuel based electricity. The fossil fuel based electricity is replaced with energy made from the combustion of wood waste produced during the conversion of poplar to bio-jet fuel. The black bar indicates the net GWP of each fuel. As indicated by the figure the use of bio-jet fuel could significantly reduce GWP when used in place of petro-jet fuel.